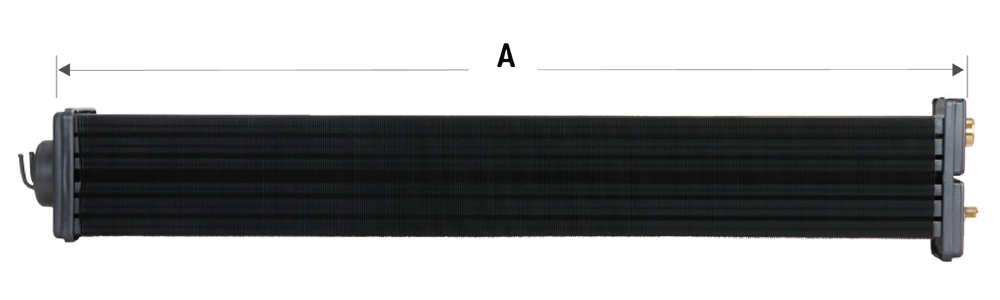

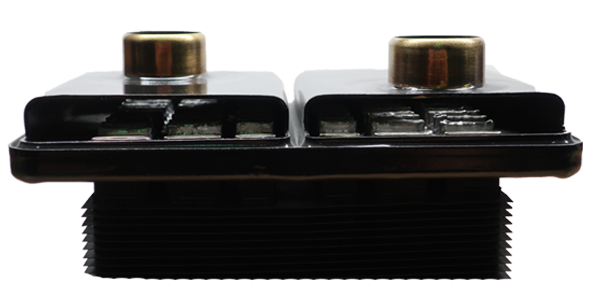

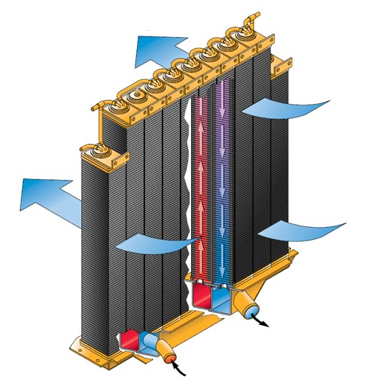

AMOCS radiators utilize a unique design and can be found on a variety of equipment including "R" series models. The key feature to this design is that it utilizes a two pass cooling system which effectively increases cooling surface area to provide greater cooling capacity over conventional one pass systems, this design is very effective in applications where there is a limited frontal surface area available.

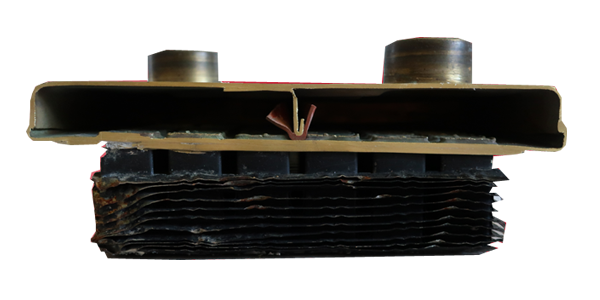

THE ZERO BYPASS GUARANTEE

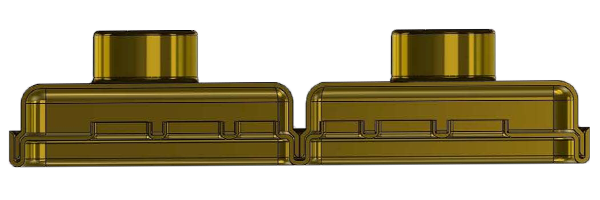

bypass. The bottom section of the radiator has been redesigned to use two soldered tanks. This completely eliminates the use of gasket baffles which are prone to failure. Procore is so confident in this design that we guarantee no coolant bypass for the lifetime of the radiator!

bypass. The bottom section of the radiator has been redesigned to use two soldered tanks. This completely eliminates the use of gasket baffles which are prone to failure. Procore is so confident in this design that we guarantee no coolant bypass for the lifetime of the radiator!